41 copper pipe epoxy coating

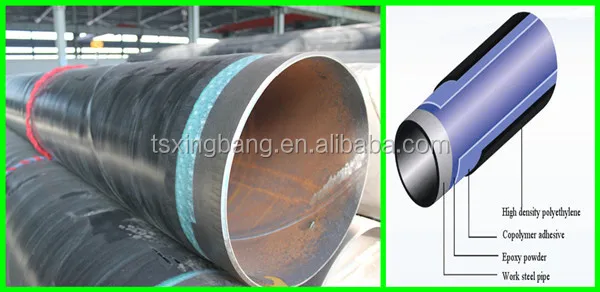

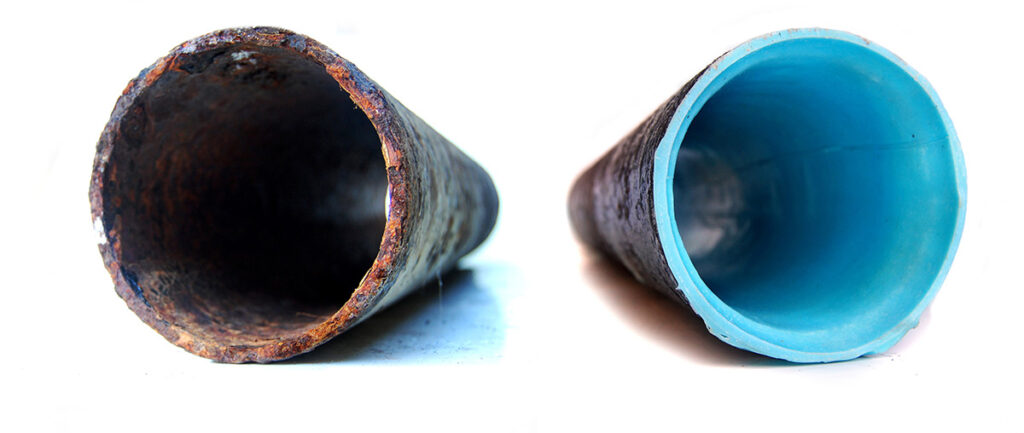

Copper Corrosion: Everything You Need to Know 15.3.2021 · Water pipe epoxy; Water pipe tape; Pipe patch kit; Supplies are solely available at most of the hardware & home amelioration stores. Ensure to utilize those products approved to patch the drinking water pipes. Product packaging generally proffers instructions on how to patch copper pipe. Well applied patch over holes in the copper pipe can last ... The Problem With Epoxy Pipe Lining | SageWater Repipe Epoxy pipe lining is often viewed as an alternative to replacing the old piping with a completely new system. In theory, the lining process involves coating the inside of the pipes with an epoxy resin to seal off pinholes and corrosion, creating a lasting solution to solving your pipe problems. That's the theory.

BENEFITS OF EPOXY PIPE COATING VS CIPP ... - Trenchless Pipe EPOXY PIPE COATING. About: Epoxy pipe coating is basically looked for as an alternative to replacing the old pipe with a completely whole new system.Talking about it with reference to theory, this process will involve coating the the pipes internally with an epoxy resin ideally to seal off the pinholes and corrosion after which plumbing is sandblasted from inside out, and silica particles that ...

Copper pipe epoxy coating

Progressive Epoxy Polymers HOMEPAGE 603-435-7199 source for EPOXY PRODUCTS, epoxy resin paint floor epoxy garage underwater, pool repairs, rot, marine epoxy - 603-435-7199 How Much Does Epoxy Pipe Lining Cost - True Cost ... Epoxy is a remarkable substance and it is assumed that epoxy can be applied correctly, but the cost of doing so may match or exceed the cost of a re-pipe in modern materials. 19. Invasiveness of Pipe Lining vs. Pipe Replacement. The claim that pipe lining is less invasive depends on what one considers invasive. Epoxy Pipe Lining | NuDrain For Internal Pipe Coating ... An internal rubber bladder is then inflated, pressing the epoxy coating against the pipe walls. Once the epoxy has cured, the bladder is deflated and removed, and the pipe lining process leaves you with a clean and seamless "pipe-within-a-pipe." "Our Cold Cure UV liners cure in just minutes!" The result is: An increase in flow rate

Copper pipe epoxy coating. Should I repipe my home? Or can I use ePIPE ... - TDT Plumbing You can re-pipe with copper. People do it with CPVC PEX, that's another product that people re-pipe all the time with. New construction homes are being put in using typically PEX or CPVC. We, actually, we're re-piping copper if you would like to go to another metallic pipe. So, there are options out there and we're here to help with those. Residential ePIPE - Florida Pipe Lining Solutions Florida's Leader in Pipe Inspections, Pipe-Cleaning, Pipe-Lining and Pipe Replacement Solutions. Get A Free Estimate Today. Based on proven barrier coating principles used by water utilities, ePIPE is focused on pipe repair using in-place restoration of small diameter pipes. Our pipe repair includes pipes as small as 6mm (1/2") in diameter. 2 Reasons Why Copper Pipes Might Need to Be Epoxy Lined ... Two Reasons Why Copper Pipes May Need to Be Lined with Epoxy Even with copper's positive benefits, there may still be instances where it could benefit from being lined with an epoxy coating. Two of the most common causes that may lead to the need to line your copper pipes include pitting corrosion and galvanic metal corrosion. 1. Pitting Corrosion Corrosion Protection & Resistance: Clear organic finishes Epoxy coatings darkened in four to six months. Silicone thermoset coatings retain good protective qualities after 62 days at 200 F or 100 hours at 300 F. Antiqued brass automotive interior trim has been protected with a thermosetting epoxy clear coating.

1-1/2" Copper or 1-1/4" Iron Pipe Black Epoxy Coated Pipe ... SKU: 112PS Category: Pipe Stays (Valley Hangers) Tags: Pipe hanger, stay, Valley Hanger. Description. Additional information. Reviews (0) This black epoxy coated stamped steel pipe stay or hanger works with 1-1/2″ Copper pipe or 1-1/4″ Iron pipe. Supplies - Spraypoxy Spraycoat FC+ is a fast curing high-performance pipe coating epoxy. Designed exclusively for the TKK-1 equipment. Spraycoat relining material is specially developed for waste- and rainwater pipes, and it is suitable for pipe materials such as PVC, clay, stainless steel, concrete, copper, and cast iron. Epoxy Coating of copper H2O pipes? - RIDGID Forum ... Re: Epoxy Coating of copper H2O pipes? mr. ace, i again spent 30 minutes on your company web site. everything points to copper pin holes and copper pipe epoxy coating. are you currently epoxy coating gal. water pipe. what percentage of jobs are copper and what percentage are galvanized steel? please keep in mind current #'s for the past year or 2. Metal Pipe - Seamless Pipe - ERW Pipe - Galvanized Pipe ... Types of Pipes and Tubular Goods There are six types of pipes and tubular goods. Standard Pipe: There are three different types of standard metal pipes - welded (ERW Pipe), seamless pipe, and galvanized pipe. They represent 10% of all tubular products. Line Pipe: Used primarily in Oil and Gas Applications. Line pipe includes ERW, FW, SAW and DSAW Pipe.

90 oz. Clear High-Gloss 2-Part Epoxy Interior Low VOC ... 1.10.2021 · Epoxy 2 gal. Water-Based Clear High Gloss 2-Part Epoxy Primer and Top Coat for Concrete Floors The Armor Epoxy is a 2-Part water based epoxy The Armor Epoxy is a 2-Part water based epoxy primer and top coat system for interior concrete floors. It can be used as a primer to other coating systems or alone as a primer and top coat. Pipe Repair Service | Internal Pipe Coating | NuLine Epoxy ... The epoxy coating is non-toxic and approved for use in cold and hot potable water applications systems down to 1/2" in pipe diameter. It is also recognized by ICC-ES for application on copper, black steel or galvanized fire sprinkler pipe from 1/2" to 12" in diameter. Aimco International - Pipe Hangers & Supports Pipe hangers, supports, ... EPOXY COATING. Designed for use with copper tubing. This coating provides a superior level of corrosion protection compared to the traditional copper plating finish. It also insulates against dissimilar metal contact, thus preventing electrolysis. CHLORAMINE CORRODES COPPER PIPES - CuraFlo Epoxy Pipe Lining. One way to resolve copper pipe corrosion is through epoxy pipelining. This lining creates a barrier that prevents water from contact with the interior wall of the copper pipe. The epoxy resin is spread through the pipe, coating its interior diameter to create a permanent inert barrier between the water and the wall of the pipe.

Nu Flow epoxy coating pipe re-lining demo - YouTube Nu Flow epoxy coating pipe re-lining demo at SA Leak Detectrion Distributors offices.

Epoxy Coating Orange County - Bill Metzger Plumbing We offer epoxy coating of hot and cold copper water line and sewer lines as an option. This application takes 2-3 days and you will have no dry wall holes and no mess to redo and clean up. Epoxy coatings are generally packaged in two parts that are mixed prior to application.

Epoxy Pipe Lining Repairs & Epoxy Pipe Coating Service in 2022 ePIPE epoxy coating can be used to treat most pipe materials. It's compatible with copper pipes, PVC, stainless steel, among most others. It's a one-size-fits-all type of solution and for this reason, most home and building owners are turning to epoxy coating to meet their versatile needs. More Affordable Than Complete Pipe Replacement

Epoxy coating copper pipes good or bad? - Ask Me Help Desk e-piping is as process of relining leaking galvanized & copper pipes with epoxy. This process has been around in some forms since the seventies. The company that did these repairs is "ACE DURAFLOW" which has been in business since the '90s & has good better business bureau rating. There website explains process fully.

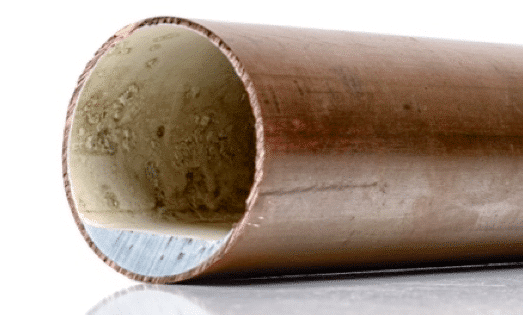

Why copper pipe protective coating is important - Heresite ... Copper pipe protective coating is important to ensure that the entire unit is protected from harsh environmental conditions, such as in wastewater treatment plants, food plants, commercial buildings near coastlines and other harsh environments where corrosion can begin in just a few months. The photo below is a perfect example.

Epoxy Coating Copper Piping rather than Re-piping I heard mention of a system that can coat the interior of copper piping with a strong epoxy. This very thin but very strong layer resists future corrosion. If this is an effective approach to reducing water damage claims, the insurance industry may offer discounts on our policies to those who have had this done.

Epoxy Coating of copper H2O pipes? - RIDGID Forum ... A few years ago I had 3 pinhole leaks in my copper pipes in 3 months time. I did some research online to find out why my 15 year old pipes were failing. It was a long story, but in the end, it was the water that caused it. While researching this, I also found articles about epoxy coating failing copper, galvanized & plastic pipes.

What is Epoxy Pipe Lining & When to Use It — Pipeline ... 9.3.2021 · Thankfully, there are preventative measures you can take instead by utilizing epoxy pipe lining. With epoxy lining, you can avoid costly emergency repairs that can take weeks to complete. Keep reading to learn about internal pipe coating, when it use it and the pros and cons of epoxy pipe lining. What is Epoxy Pipe Coating: What to Know

› productsJ-B Weld Products | J-B Weld FiberWeld 1" Pipe Repair Cast ... Ultimate Copper Gasket Maker & Sealant Add to Cart. ... UltraRez UV-Resistant Coating & Casting Epoxy 128 fl oz Add to Cart.

How to Apply Copper Pipe Repair Epoxy | DoItYourself.com Copper pipe repair is simply done by using the right epoxy. This epoxy mixture is available at your local hardware store. Below are the steps on how to apply this epoxy to the leaky pipe. Follow these steps, and you are sure to have a pipe that's back to normal in no time. Step 1 - Locate and Check

Epoxy Internal Coatings For Copper House Water Lines To ... Conversations. All groups and messages

Will Using Dissimilar Plumbing Pipe Metals Accelerate Pipe ... 23.7.2020 · There are three commonly used metals for potable water plumbing pipes, including stainless steel, copper, and brass. These metals are used because of their durability and long lifespans. However, mixing these metals is not generally advised due to the potential for sudden pipe corrosion and discolored water.

How Much Does Epoxy Pipe Coating Cost ... - Pipe ... Benefits of Epoxy Pipe Coating Epoxy pipe coating creates a barrier within your existing pipe structure. This prevents pinhole leaks, reduces copper, iron, and lead leaching into your water supply. It's also minimally invasive; you often don't have to jackhammer or cut open drywall to access the pipes.

Opinions of Epoxy for copper pipes? He offers to replumb the whole house with PEX or to coat the whole copper system with epoxy. The cost is about the same, a little more for the PEX because of all the dry wall r&r. He said with an existing copper system the epoxy coating is the only sure way to prevent leaks. It's becoming more popular all the time and is well established.

› products › viewHigh Performance Protective Coating Products | Tnemec ... Abrasion resistant, high solids, epoxy coating which offers high-build edge protection and excellent corrosion resistance. Contains glass flake and aluminum oxide for improved film integrity. For use on the interior and exterior of steel or concrete tanks, pipes, and other heavy-duty equipment in industrial service.

Pipe Diameter Charts | EzyStrut Pipe Diameter Charts. Understanding pipe sizes and weights is easy with our helpful bore and diameter charts... EzyStrut's pipe clamps and heavy duty support systems suit pipes of different materials and sizes, and are measured by Nominal Bore (NB) and Outside Diameter (ØD).. Our charts below are designed to make it easy to select the correct clamps for a project's …

Epoxy Internal Coatings For Copper House Water Lines To ... "Water supply pipe epoxy relining generally costs about the same as removing the old pipes and installing new ones; including the cost of average surface refinishing after the fact.

Copper Epoxy | Lining for Copper Pipes - Coating & Repair ... Copper epoxy works by adhering to the inside of pipes. If build-up remains, the copper pipe epoxy coating will be uneven and create the risk of future corrosion. The process to prepare pipes and apply epoxy pipeliner to repair pinholes in copper pipe isn't quick but the result provides protection for 40-60 years.

Epoxy Internal Coating For Stopping House Pinhole Leaks ... Plumbing and Piping - Epoxy Internal Coating For Stopping House Pinhole Leaks, & A Few Other Questions - Hello, Have had a few pinhole leaks in house Copper water pipes. House is 35 yrs old, and was apparently built with the thin wall Type M Copper pipe. Hope to avoid re-plumbing the entire house. Anyone know

Epoxy Pipe Lining | NuDrain For Internal Pipe Coating ... An internal rubber bladder is then inflated, pressing the epoxy coating against the pipe walls. Once the epoxy has cured, the bladder is deflated and removed, and the pipe lining process leaves you with a clean and seamless "pipe-within-a-pipe." "Our Cold Cure UV liners cure in just minutes!" The result is: An increase in flow rate

How Much Does Epoxy Pipe Lining Cost - True Cost ... Epoxy is a remarkable substance and it is assumed that epoxy can be applied correctly, but the cost of doing so may match or exceed the cost of a re-pipe in modern materials. 19. Invasiveness of Pipe Lining vs. Pipe Replacement. The claim that pipe lining is less invasive depends on what one considers invasive.

Progressive Epoxy Polymers HOMEPAGE 603-435-7199 source for EPOXY PRODUCTS, epoxy resin paint floor epoxy garage underwater, pool repairs, rot, marine epoxy - 603-435-7199

.png)

0 Response to "41 copper pipe epoxy coating"

Post a Comment